PCB Test & Measurement Seite 158

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.Klicken Sie hier um zur Online-Version zu gelangen.

Inhalt

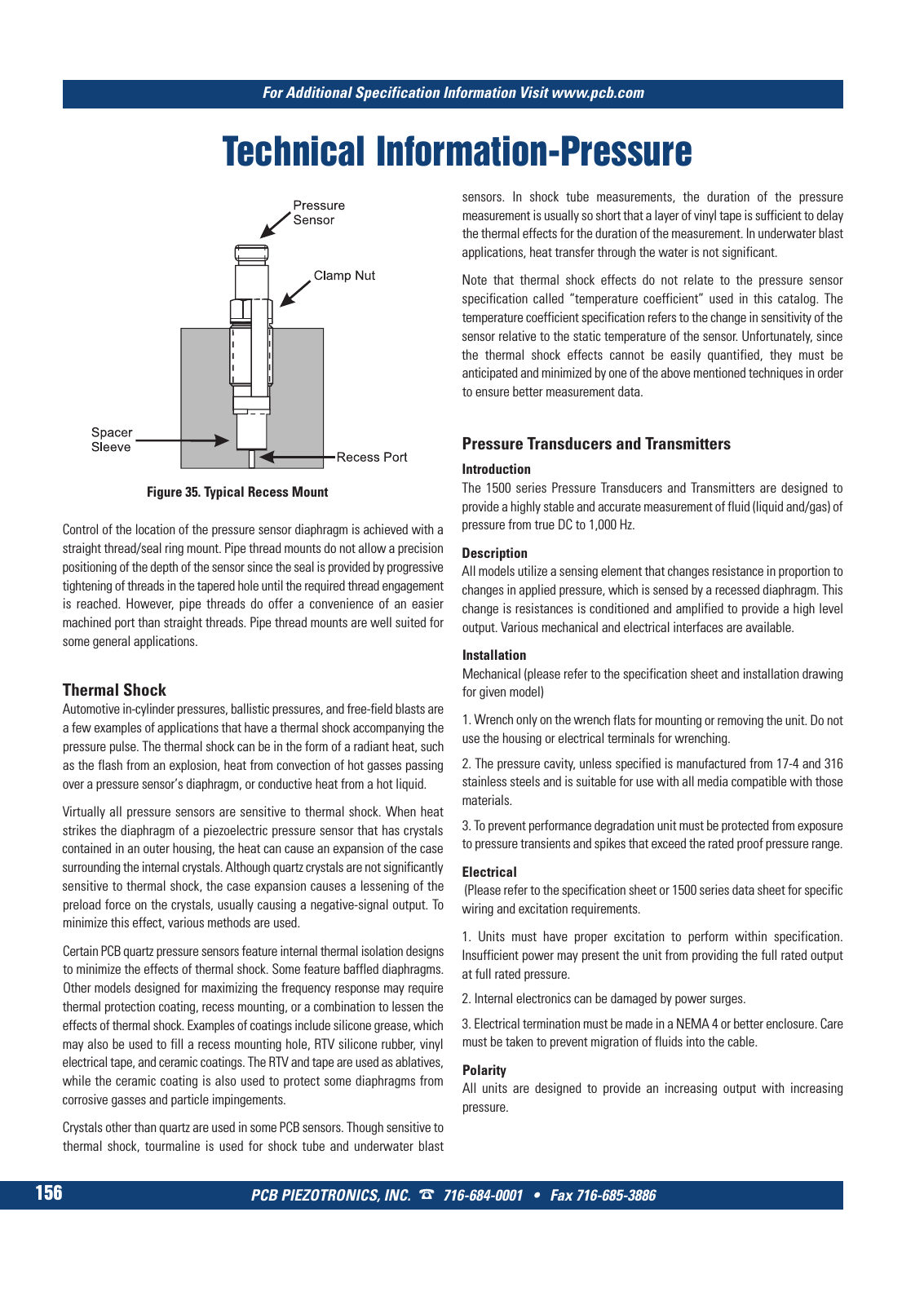

PCB PIEZOTRONICS INC 716 684 0001 Fax 716 685 3886 For Additional Specification Information Visit www pcb com 156 Technical Information Pressure Figure 35 Typical Recess Mount Control of the location of the pressure sensor diaphragm is achieved with a straight thread seal ring mount Pipe thread mounts do not allow a precision positioning of the depth of the sensor since the seal is provided by progressive tightening of threads in the tapered hole until the required thread engagement is reached However pipe threads do offer a convenience of an easier machined port than straight threads Pipe thread mounts are well suited for some general applications Thermal Shock Automotive in cylinder pressures ballistic pressures and free field blasts are a few examples of applications that have a thermal shock accompanying the pressure pulse The thermal shock can be in the form of a radiant heat such as the flash from an explosion heat from convection of hot gasses passing over a pressure sensor s diaphragm or conductive heat from a hot liquid Virtually all pressure sensors are sensitive to thermal shock When heat strikes the diaphragm of a piezoelectric pressure sensor that has crystals contained in an outer housing the heat can cause an expansion of the case surrounding the internal crystals Although quartz crystals are not significantly sensitive to thermal shock the case expansion causes a lessening of the preload force on the crystals usually causing a negative signal output To minimize this effect various methods are used Certain PCB quartz pressure sensors feature internal thermal isolation designs to minimize the effects of thermal shock Some feature baffled diaphragms Other models designed for maximizing the frequency response may require thermal protection coating recess mounting or a combination to lessen the effects of thermal shock Examples of coatings include silicone grease which may also be used to fill a recess mounting hole RTV silicone rubber vinyl electrical tape and ceramic coatings The RTV and tape are used as ablatives while the ceramic coating is also used to protect some diaphragms from corrosive gasses and particle impingements Crystals other than quartz are used in some PCB sensors Though sensitive to thermal shock tourmaline is used for shock tube and underwater blast sensors In shock tube measurements the duration of the pressure measurement is usually so short that a layer of vinyl tape is sufficient to delay the thermal effects for the duration of the measurement In underwater blast applications heat transfer through the water is not significant Note that thermal shock effects do not relate to the pressure sensor specification called temperature coefficient used in this catalog The temperature coefficient specification refers to the change in sensitivity of the sensor relative to the static temperature of the sensor Unfortunately since the thermal shock effects cannot be easily quantified they must be anticipated and minimized by one of the above mentioned techniques in order to ensure better measurement data Pressure Transducers and Transmitters Introduction The 1500 series Pressure Transducers and Transmitters are designed to provide a highly stable and accurate measurement of fluid liquid and gas of pressure from true DC to 1 000 Hz Description All models utilize a sensing element that changes resistance in proportion to changes in applied pressure which is sensed by a recessed diaphragm This change is resistances is conditioned and amplified to provide a high level output Various mechanical and electrical interfaces are available Installation Mechanical please refer to the specification sheet and installation drawing for given model 1 Wrench only on the wrench flats for mounting or removing the unit Do not use the housing or electrical terminals for wrenching 2 The pressure cavity unless specified is manufactured from 17 4 and 316 stainless steels and is suitable for use with all media compatible with those materials 3 To prevent performance degradation unit must be protected from exposure to pressure transients and spikes that exceed the rated proof pressure range Electrical Please refer to the specification sheet or 1500 series data sheet for specific wiring and excitation requirements 1 Units must have proper excitation to perform within specification Insufficient power may present the unit from providing the full rated output at full rated pressure 2 Internal electronics can be damaged by power surges 3 Electrical termination must be made in a NEMA 4 or better enclosure Care must be taken to prevent migration of fluids into the cable Polarity All units are designed to provide an increasing output with increasing pressure 9 T Mcatalog 2011 Seite 125 166 SYN G500 21 04 11 18 04 Seite 162