PCB Test & Measurement Seite 157

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.Klicken Sie hier um zur Online-Version zu gelangen.

Inhalt

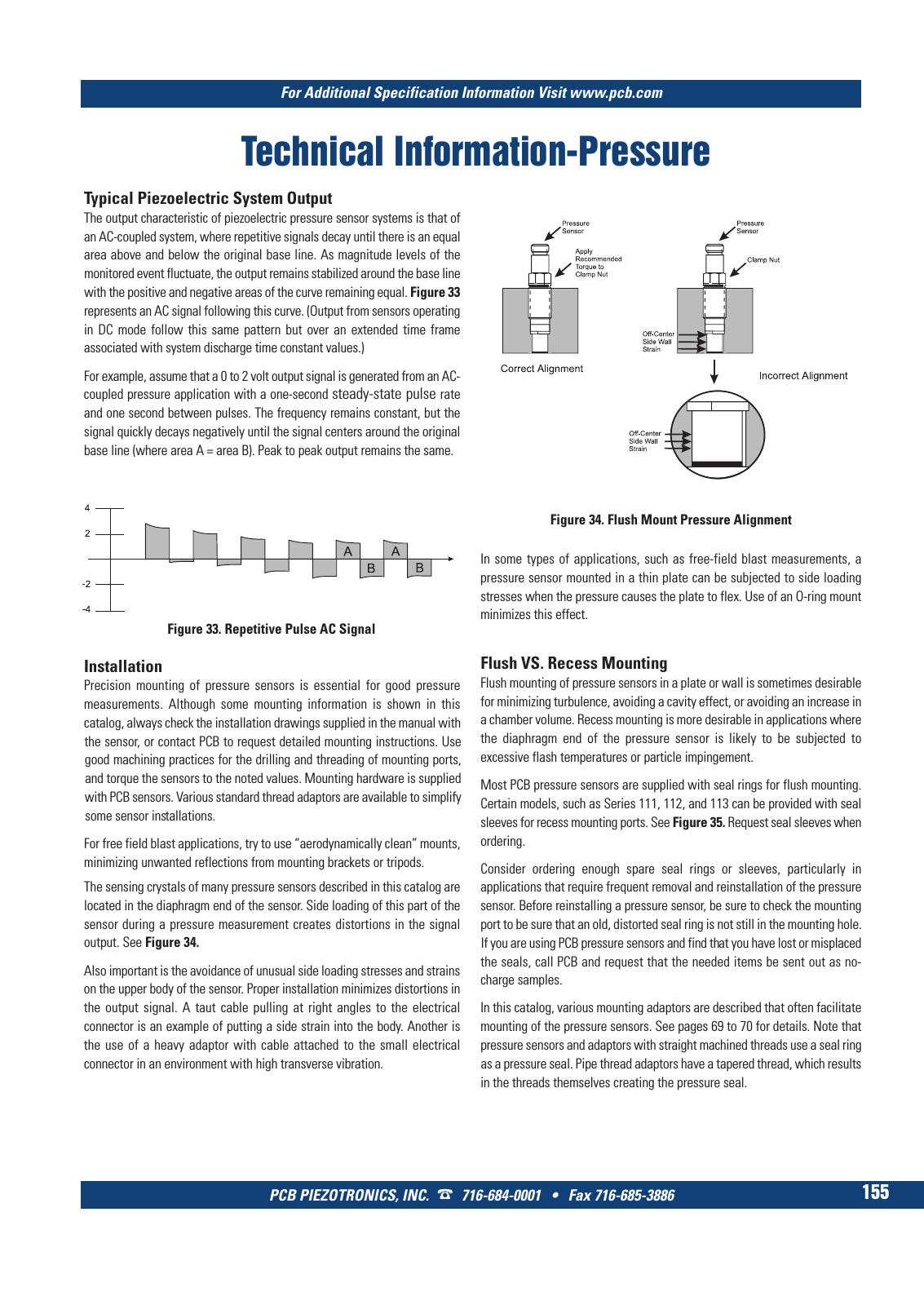

For Additional Specification Information Visit www pcb com PCB PIEZOTRONICS INC 716 684 0001 Fax 716 685 3886 155 Technical Information Pressure Typical Piezoelectric System Output The output characteristic of piezoelectric pressure sensor systems is that of an AC coupled system where repetitive signals decay until there is an equal area above and below the original base line As magnitude levels of the monitored event fluctuate the output remains stabilized around the base line with the positive and negative areas of the curve remaining equal Figure 33 represents an AC signal following this curve Output from sensors operating in DC mode follow this same pattern but over an extended time frame associated with system discharge time constant values For example assume that a 0 to 2 volt output signal is generated from an AC coupled pressure application with a one second steady state pulse rate and one second between pulses The frequency remains constant but the signal quickly decays negatively until the signal centers around the original base line where area A area B Peak to peak output remains the same Installation Precision mounting of pressure sensors is essential for good pressure measurements Although some mounting information is shown in this catalog always check the installation drawings supplied in the manual with the sensor or contact PCB to request detailed mounting instructions Use good machining practices for the drilling and threading of mounting ports and torque the sensors to the noted values Mounting hardware is supplied with PCB sensors Various standard thread adaptors are available to simplify some sensor installations For free field blast applications try to use aerodynamically clean mounts minimizing unwanted reflections from mounting brackets or tripods The sensing crystals of many pressure sensors described in this catalog are located in the diaphragm end of the sensor Side loading of this part of the sensor during a pressure measurement creates distortions in the signal output See Figure 34 Also important is the avoidance of unusual side loading stresses and strains on the upper body of the sensor Proper installation minimizes distortions in the output signal A taut cable pulling at right angles to the electrical connector is an example of putting a side strain into the body Another is the use of a heavy adaptor with cable attached to the small electrical connector in an environment with high transverse vibration In some types of applications such as free field blast measurements a pressure sensor mounted in a thin plate can be subjected to side loading stresses when the pressure causes the plate to flex Use of an O ring mount minimizes this effect Flush VS Recess Mounting Flush mounting of pressure sensors in a plate or wall is sometimes desirable for minimizing turbulence avoiding a cavity effect or avoiding an increase in a chamber volume Recess mounting is more desirable in applications where the diaphragm end of the pressure sensor is likely to be subjected to excessive flash temperatures or particle impingement Most PCB pressure sensors are supplied with seal rings for flush mounting Certain models such as Series 111 112 and 113 can be provided with seal sleeves for recess mounting ports See Figure 35 Request seal sleeves when ordering Consider ordering enough spare seal rings or sleeves particularly in applications that require frequent removal and reinstallation of the pressure sensor Before reinstalling a pressure sensor be sure to check the mounting port to be sure that an old distorted seal ring is not still in the mounting hole If you are using PCB pressure sensors and find that you have lost or misplaced the seals call PCB and request that the needed items be sent out as no charge samples In this catalog various mounting adaptors are described that often facilitate mounting of the pressure sensors See pages 69 to 70 for details Note that pressure sensors and adaptors with straight machined threads use a seal ring as a pressure seal Pipe thread adaptors have a tapered thread which results in the threads themselves creating the pressure seal Figure 34 Flush Mount Pressure Alignment Figure 33 Repetitive Pulse AC Signal 9 T Mcatalog 2011 Seite 125 166 SYN G500 21 04 11 18 04 Seite 161