PCB Test & Measurement Seite 152

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.Klicken Sie hier um zur Online-Version zu gelangen.

Inhalt

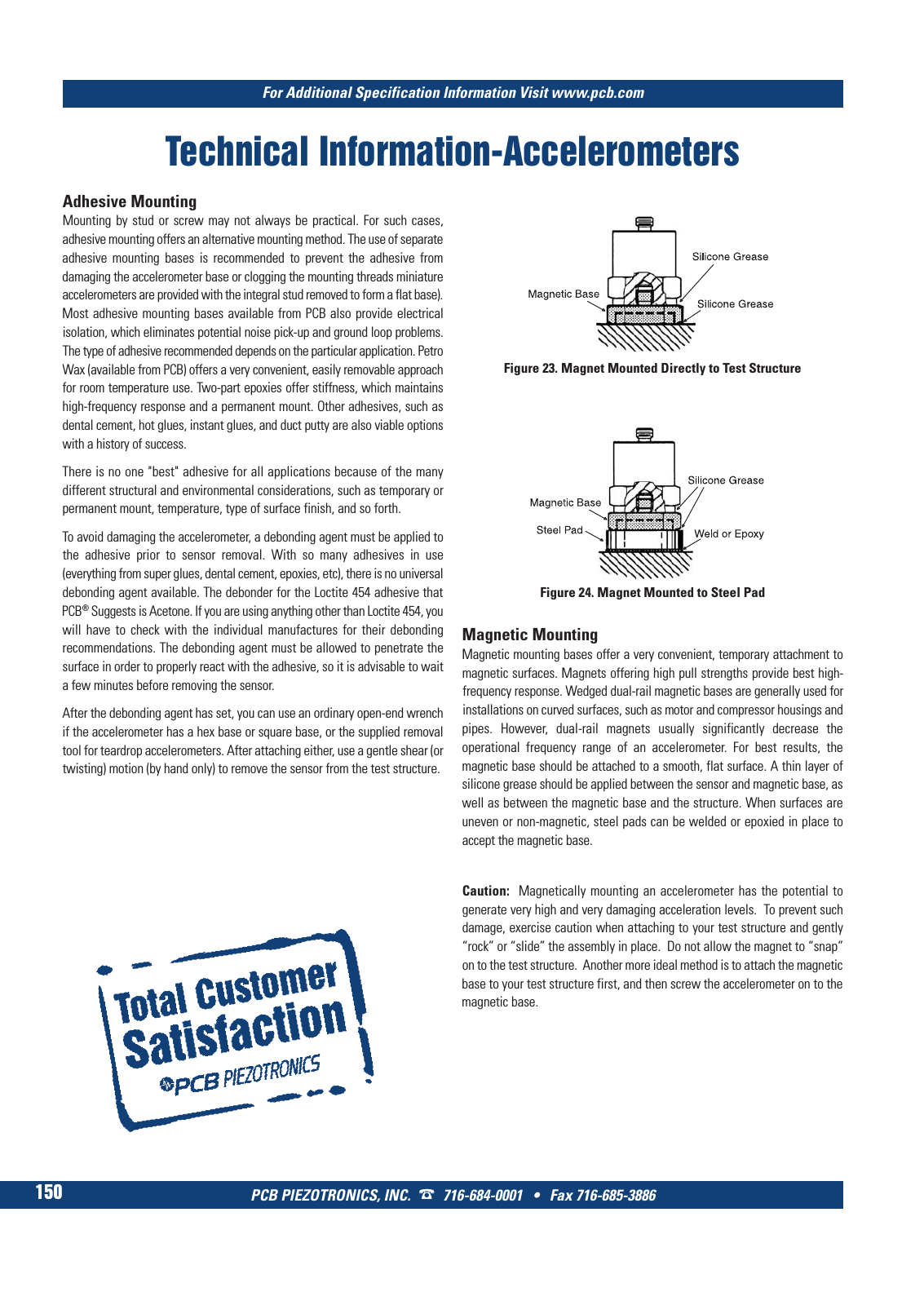

Technical Information Accelerometers PCB PIEZOTRONICS INC 716 684 0001 Fax 716 685 3886 For Additional Specification Information Visit www pcb com 150 Magnetic Mounting Magnetic mounting bases offer a very convenient temporary attachment to magnetic surfaces Magnets offering high pull strengths provide best high frequency response Wedged dual rail magnetic bases are generally used for installations on curved surfaces such as motor and compressor housings and pipes However dual rail magnets usually significantly decrease the operational frequency range of an accelerometer For best results the magnetic base should be attached to a smooth flat surface A thin layer of silicone grease should be applied between the sensor and magnetic base as well as between the magnetic base and the structure When surfaces are uneven or non magnetic steel pads can be welded or epoxied in place to accept the magnetic base Caution Magnetically mounting an accelerometer has the potential to generate very high and very damaging acceleration levels To prevent such damage exercise caution when attaching to your test structure and gently rock or slide the assembly in place Do not allow the magnet to snap on to the test structure Another more ideal method is to attach the magnetic base to your test structure first and then screw the accelerometer on to the magnetic base Adhesive Mounting Mounting by stud or screw may not always be practical For such cases adhesive mounting offers an alternative mounting method The use of separate adhesive mounting bases is recommended to prevent the adhesive from damaging the accelerometer base or clogging the mounting threads miniature accelerometers are provided with the integral stud removed to form a flat base Most adhesive mounting bases available from PCB also provide electrical isolation which eliminates potential noise pick up and ground loop problems The type of adhesive recommended depends on the particular application Petro Wax available from PCB offers a very convenient easily removable approach for room temperature use Two part epoxies offer stiffness which maintains high frequency response and a permanent mount Other adhesives such as dental cement hot glues instant glues and duct putty are also viable options with a history of success There is no one best adhesive for all applications because of the many different structural and environmental considerations such as temporary or permanent mount temperature type of surface finish and so forth To avoid damaging the accelerometer a debonding agent must be applied to the adhesive prior to sensor removal With so many adhesives in use everything from super glues dental cement epoxies etc there is no universal debonding agent available The debonder for the Loctite 454 adhesive that PCB Suggests is Acetone If you are using anything other than Loctite 454 you will have to check with the individual manufactures for their debonding recommendations The debonding agent must be allowed to penetrate the surface in order to properly react with the adhesive so it is advisable to wait a few minutes before removing the sensor After the debonding agent has set you can use an ordinary open end wrench if the accelerometer has a hex base or square base or the supplied removal tool for teardrop accelerometers After attaching either use a gentle shear or twisting motion by hand only to remove the sensor from the test structure Figure 23 Magnet Mounted Directly to Test Structure Figure 24 Magnet Mounted to Steel Pad 9 T Mcatalog 2011 Seite 125 166 SYN G500 21 04 11 18 04 Seite 156