IMI Industrial Vibration Sensors Katalog Seite 83

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.Klicken Sie hier um zur Online-Version zu gelangen.

Inhalt

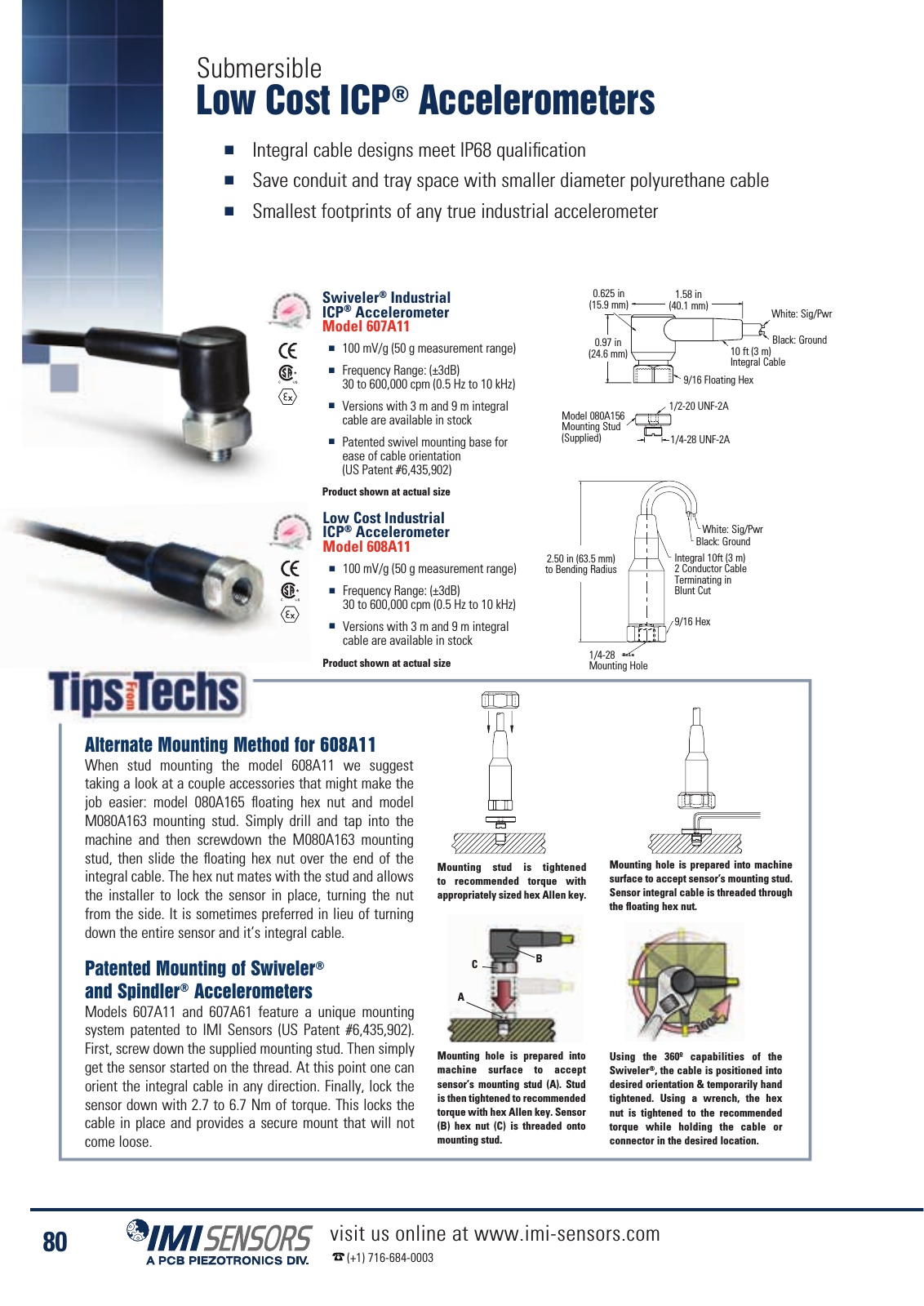

Low Cost ICP Accelerometers n Integral cable designs meet IP68 qualification n Save conduit and tray space with smaller diameter polyurethane cable n Smallest footprints of any true industrial accelerometer 2 50 63 5 to bending radius 9 16 HEX Black Ground White Sig Power Integral 10 ft 3 m 2 conductor cable terminating in blunt cut 1 4 28 Mtg Hole IECEx IECEx IECEx IECEx Low Cost Industrial ICP Accelerometer Model 608A11 n 100 mV g 50 g measurement range n Frequency Range 3dB 30 to 600 000 cpm 0 5 Hz to 10 kHz n Versions with 3 m and 9 m integral cable are available in stock Product shown at actual size Patented Mounting of Swiveler and Spindler Accelerometers Models 607A11 and 607A61 feature a unique mounting system patented to IMI Sensors US Patent 6 435 902 First screw down the supplied mounting stud Then simply get the sensor started on the thread At this point one can orient the integral cable in any direction Finally lock the sensor down with 2 7 to 6 7 Nm of torque This locks the cable in place and provides a secure mount that will not come loose Submersible IECEx IECEx IECEx IECEx Swiveler Industrial ICP Accelerometer Model 607A11 n 100 mV g 50 g measurement range n Frequency Range 3dB 30 to 600 000 cpm 0 5 Hz to 10 kHz n Versions with 3 m and 9 m integral cable are available in stock n Patented swivel mounting base for ease of cable orientation US Patent 6 435 902 Product shown at actual size Alternate Mounting Method for 608A11 When stud mounting the model 608A11 we suggest taking a look at a couple accessories that might make the job easier model 080A165 floating hex nut and model M080A163 mounting stud Simply drill and tap into the machine and then screwdown the M080A163 mounting stud then slide the floating hex nut over the end of the integral cable The hex nut mates with the stud and allows the installer to lock the sensor in place turning the nut from the side It is sometimes preferred in lieu of turning down the entire sensor and it s integral cable Mounting hole is prepared into machine surface to accept sensor s mounting stud A Stud is then tightened to recommended torque with hex Allen key Sensor B hex nut C is threaded onto mounting stud Using the 360º capabilities of the Swiveler the cable is positioned into desired orientation temporarily hand tightened Using a wrench the hex nut is tightened to the recommended torque while holding the cable or connector in the desired location BC A Mounting stud is tightened to recommended torque with appropriately sized hex Allen key Mounting hole is prepared into machine surface to accept sensor s mounting stud Sensor integral cable is threaded through the floating hex nut Model 080A156 Mounting Stud Supplied 10 ft 3 m Integral Cable Integral 10ft 3 m 2 Conductor Cable Terminating in Blunt Cut 9 16 Floating Hex 0 625 in 15 9 mm 1 58 in 40 1 mm 0 97 in 24 6 mm 2 50 in 63 5 mm to Bending Radius White Sig Pwr Black Ground White Sig Pwr Black Ground 1 2 20 UNF 2A 1 4 28 UNF 2A 9 16 Hex 80 1 4 28 Mounting Hole visit us online at www imi sensors com 1 716 684 0003